Application of Network Control Technology in Vulcanizer Control System

Application of Network Control Technology in Vulcanizer Control System

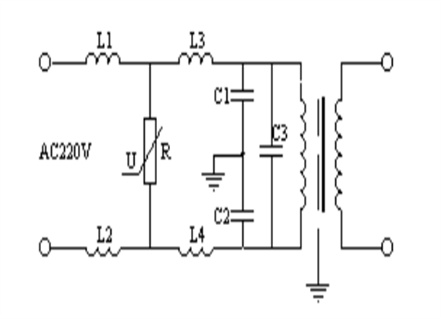

Processing of power supply by PLC

Processing of power supply by PLC

The low-pass filter can absorb most of the " burrs " of the power supply

The low-pass filter can absorb most of the " burrs " of the power supply

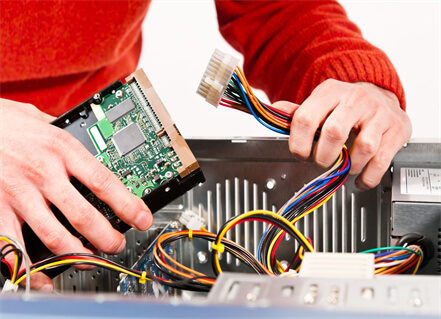

The application of the PLCs

The application of the PLCs

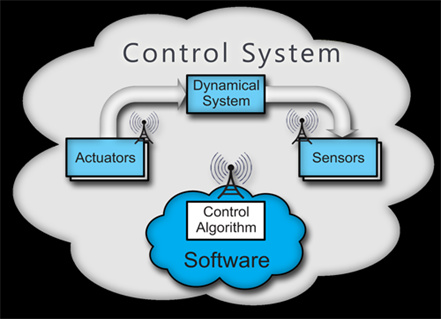

The working principle of the PLC system

The working principle of the PLC system

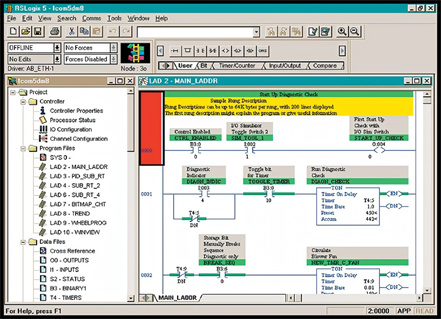

Software process

Software process

Application of PLC, DCS and FCS in metallurgical process control

Application of PLC, DCS and FCS in metallurgical process control

The control scale and complexity of the process control system

The control scale and complexity of the process control system

Address: WING INDUSTRY BLDG 3, TSUN WEN ROAD, TUEN MUN NT, HONG KONG

Address: WING INDUSTRY BLDG 3, TSUN WEN ROAD, TUEN MUN NT, HONG KONG

Tel: 0086 19116398948

Tel: 0086 19116398948

Email: sh_plc@163.com

Email: sh_plc@163.com

Contact: Vivi Wong

Contact: Vivi Wong